COLUMN

Observation of Cross-Sectional Morphology of the 3D Metal Printing Products

2018.01.15

3D Printing Direct Metal Printing

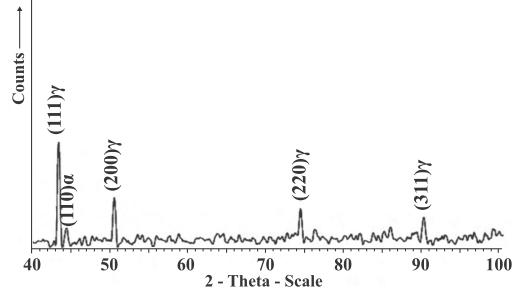

3D metal printing uses laser (or electron beam) to melt metal powder.

Every material has different properties such as melting point and optical absorption rate.

Therefore, it is necessary to adjust parameters each times when you choose a new material.

There are many parameters, such as laser power and scan speed…etc, therefore it is essential to adjust these parameters to suitable values in order to make product with high density, and good properties.

In addition, optimizing of the design for products’ shape and support arrangement is necessary.

The tuned parameter recipe will be provided for certificated material by 3D printing machine manufacturers. But if you choose not certificated material, you have to adjust the parameters by yourself or outsource it. To create your own parameter recipe, it is crucial to check the internal state of the products.

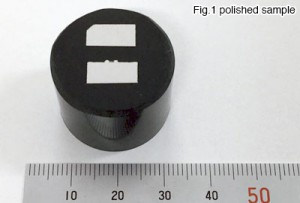

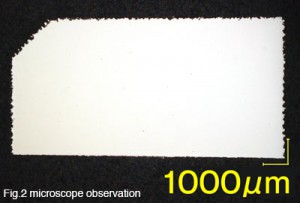

SOLIZE conducts microscope observation of the polished cross-sectional morphology to check the melted state of powder, presence of pores and defects…etc.

We adjust parameter recipe to create more high density products.

For example, our four materials currently in sale, (Maraging Steel/ 17-4PH/ AlSi12/ Inconel718PDF)

all achieve a density of more than 99%.