COLUMN

Difference in Mechanical Properties of Aluminum in 3D Printing and Die Casting

2018.02.15

3D Printing Direct Metal Printing

Is it possible to use 3D printed metal parts as conventional metal parts without practical problems?

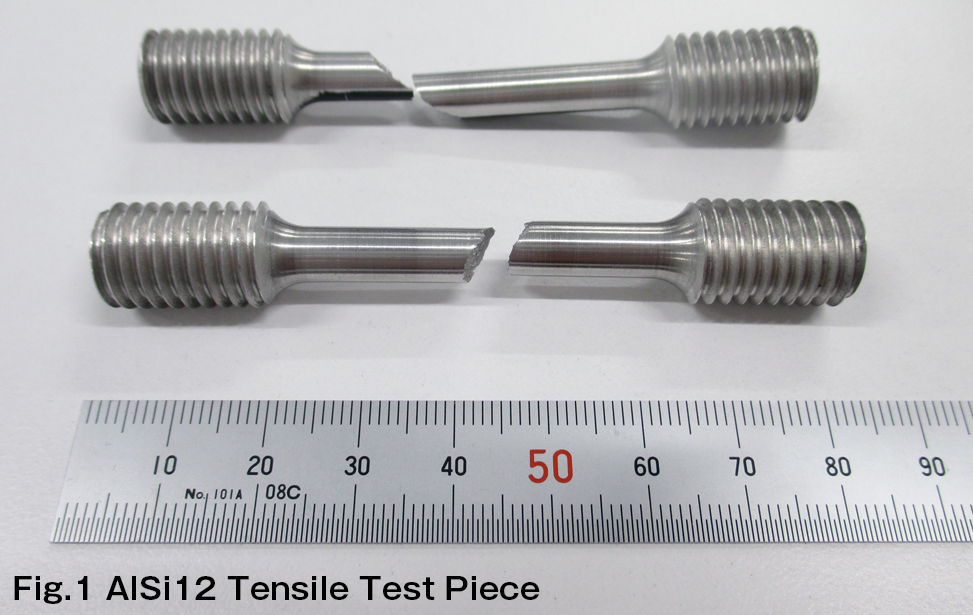

To find an answer to this question, there are several ways to measure important physical properties in mechanical product design. Among these ways, we used tensile test, which is commonly used, to check the mechanical property of the 3D print product.

The shapes of the test piece are determined by standards. In SOLIZE, we conduct tensile test according to ASTM E8.

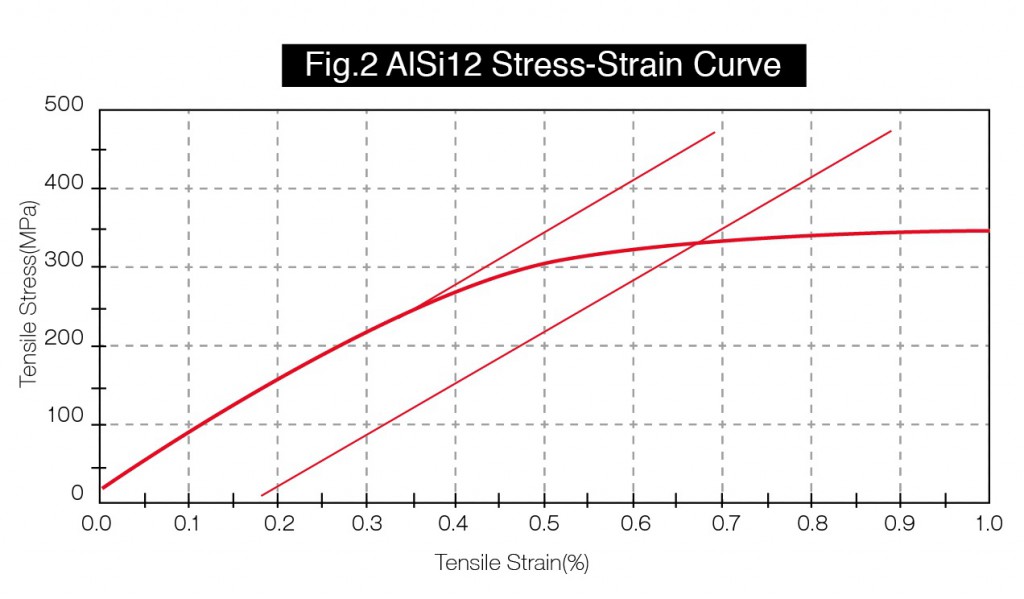

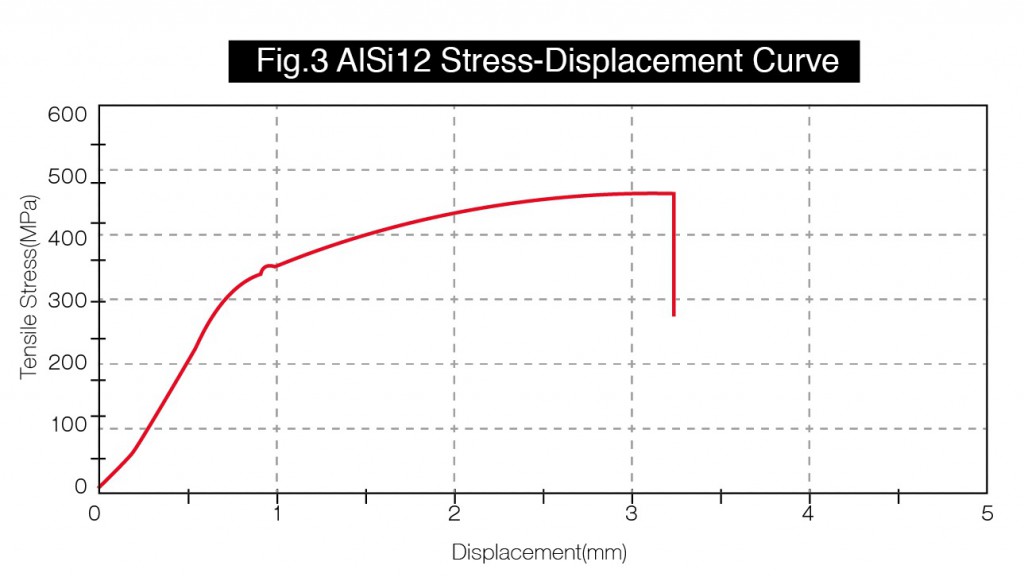

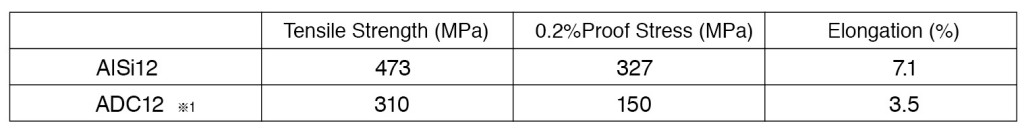

Graph above shows the tensile test result of 3D printed AlSi12 test piece. We compared this result with tensile test result of ADC12, which is a material most widely used in die casting.

※1 Source from Japan Die Casting Association http://www.diecasting.or.jp/diecast/pdf/book/pdf_set023-0.pdf

Even though both materials are aluminum-silicon alloy and have similar composition, strength and elongation came out to be very different. These differences in strength and elongation are considered to be caused by the presence of the distinctive structure of additive manufacturing.