COLUMN

Different Types of 3D Metal Printing and Melt Pools

2018.05.15

3D Printing Direct Metal Printing

In 3D metal printing, there are mainly two types of methods,

Powder Bed Fusion (PBF) and Direct Energy Deposition (DED).

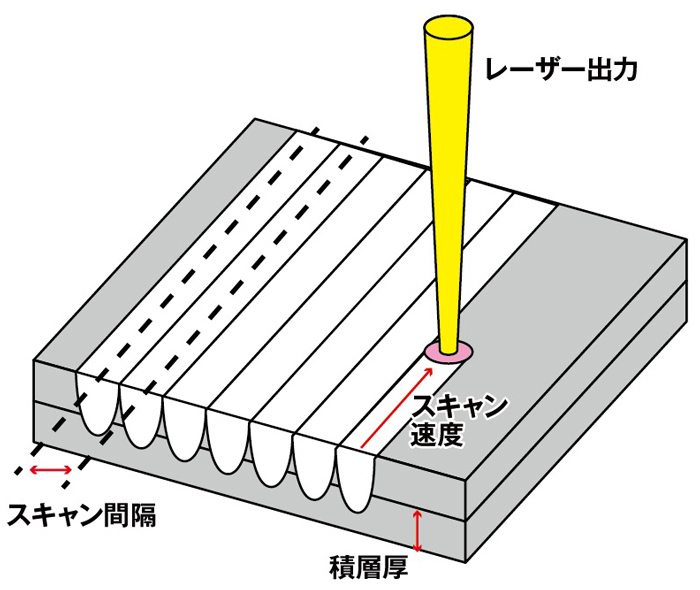

PBF uses laser or electron beam to melt metal powder layer by layer.

In DED, deposited metal powder is melted by laser or arc-beam and melted metal is added up to make a product.

These two methods uses different scan speed, which is very important parameter regarding melt pool.

For PBF that uses laser, scan speed is about 1m/s, but DED scan speed is about 10㎜/s.

Because of the scan speed, it shapes different types of melt pool.

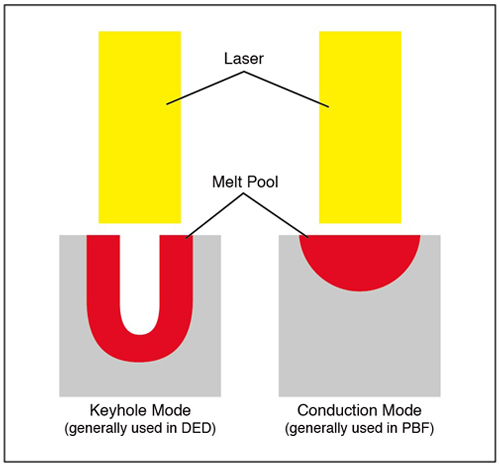

DED uses keyhole mode which is same type of melt pool as welding.

The melt pool with keyhole made by vaporized alloy has high efficiency of laser absorption because laser is reflected and absorbed many times inside the hole. It means high efficiency welding.

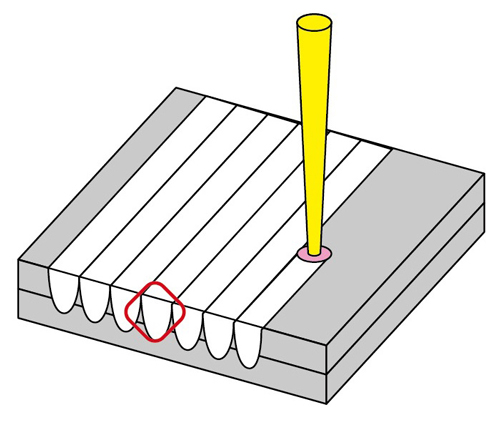

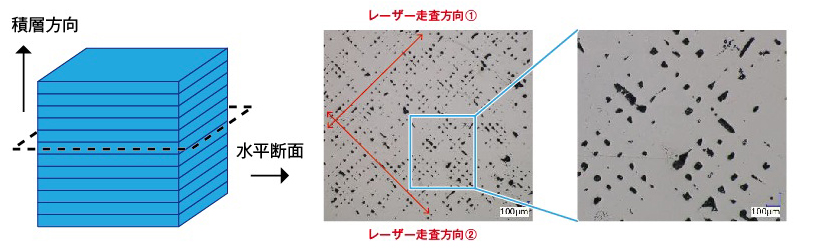

However, keyhole mode is not used in PBF because very fast scan speed makes the keyhole unstable and leaves void.

For this reason, conduction mode, which does not have any hole inside the melt pool, is used in PBF.

↑Fig.1 Types of Melt Pool

↑Fig.1 Types of Melt Pool

In case of using conduction mode, high thermal conductivity alloy like aluminum is more difficult to build than other materials. High thermal conductivity prevents powder from increasing the temperature and makes melt pool smaller and unstable.

But setting high energy input to increase temperature may cause unexpected keyhole and voids.

So when using the high thermal conductivity alloy, we need to be careful of adjustment of parameters.