COLUMN

The Feature of Roller Powder Feeding System

2018.06.01

3D Printing Direct Metal Printing

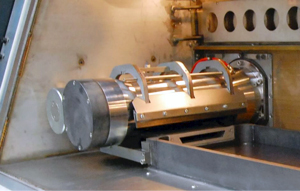

Roller type powder feeding system is used in 3D Systems’ metal 3D printer (Fig.1).

This system enables small and non-spherical powder to be used in 3D printing.

Fig.1 Roller feeding System of 3D Systems Metal 3D Printer

Fig.1 Roller feeding System of 3D Systems Metal 3D Printer

When you want to use small powder in blade type feeding system, small powder tends to aggregate, creating large lump and scratching the powder bed. This means you cannot create uniform powder bed.

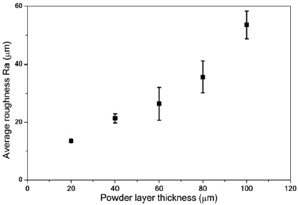

However, by using roller feeding system, the roller breaks the aggregated lump. The use of smaller powder makes it possible to create thinner layer and this improves the surface roughness of the parts.

(Fig.2, Simon Hoeges et al.,2017)[1].

Fig.2 Average surface roughness v.s. Powder layer thickness[1]

Fig.2 Average surface roughness v.s. Powder layer thickness[1]

When you want to use low cost powder such as water atomized powder, the shape of powder is non-spherical.

Non-spherical powder will not be compressed when it is just spread over the build stage. But during the feeding process, the roller system compresses the powder 20-30% so it can make highly condensed layer.

[1] Simon Hoeges, Alex Zwiren and Chris Schade, 2017, Metal Powder Report, Vol.72, Issue 2,p.111-117