Fast and accurate shape search by our original AI algorithm and easy-to-use analysis features

bring out the value of your 3D data and greatly improves the efficiency of your work.

Are you making effective use of

your ever-increasing 3D data?

Data retrieval

takes time

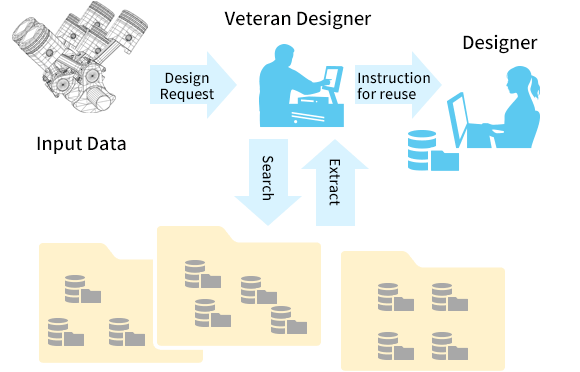

Historical development data is maintained in a proprietary manner, requiring a lot of time and effort for data retrieval.

Data maintenance and management is costly and time-consuming

The amount of data is enormous and a comprehensive system implementation would require a large-scale, cross-departmental effort, straining daily development operations.

Categorization of past data and standardization are

not progressing

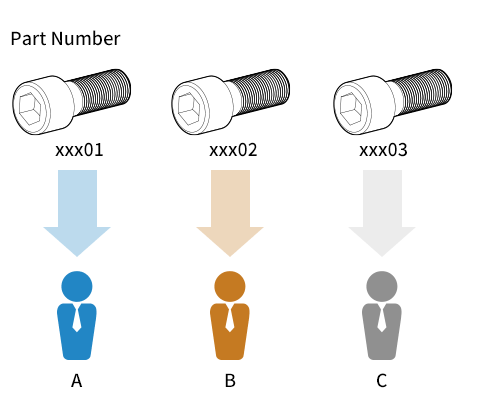

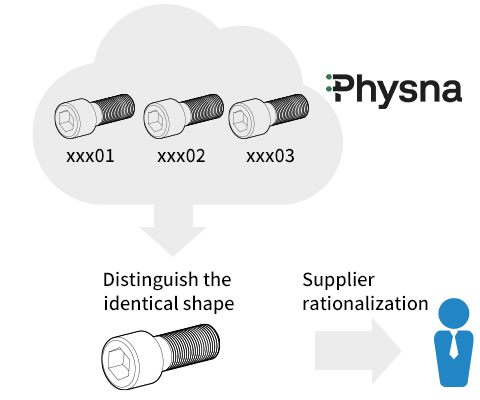

Absence of effective utilization of data results in duplication and lack of standardisation in design, purchasing, procurement and manufacturing processes.

Retrieving and organizing data becomes time consuming,

resulting in a chronic decline in the intellectual productivity of engineers.

What is Physna?

What is Physna?

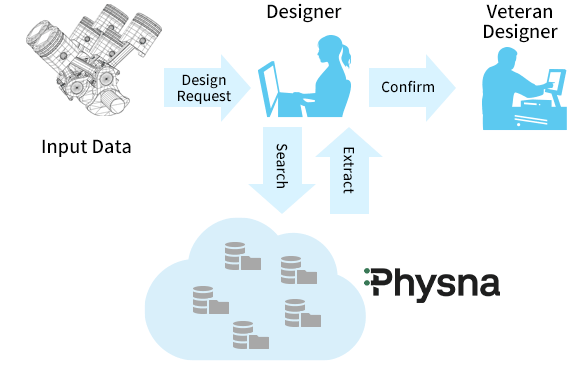

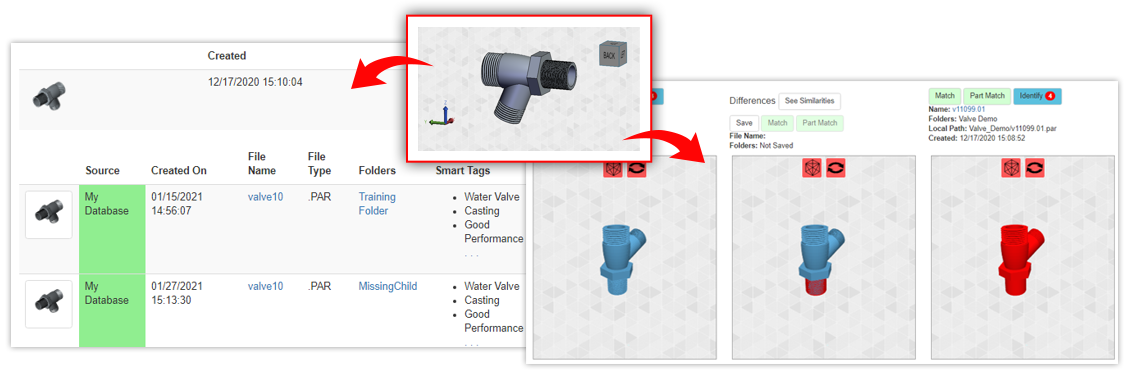

Physna is a new 3D data management solution that enables multidimensional search and comparison using 3D shape as a key.

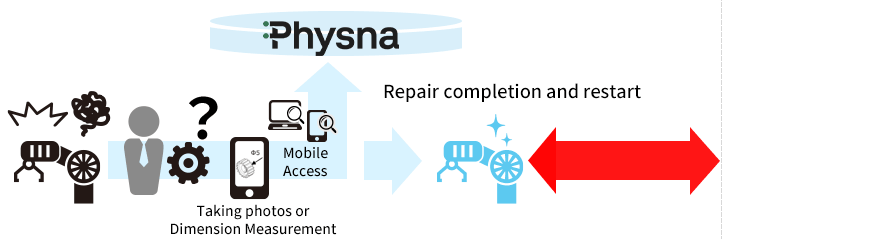

Physna, with its unique algorithms and advanced deep learning technology codifies 3D data enabling functionalities such as search, comparison, prediction and analysis of internal structures within parts and assemblies of your 3D data set. In addition, AI learning based on tagged metadata and 3D data enables easy 3D data search using only nomenclature such as part names/part numbers, so it can be used by non-CAD users as well. The 3D data set built on the cloud can be utilized without depending on CAD systems such as PLM/PDM, allowing easy access to a large amount of past manufacturing data. This will significantly enhance operational efficiency in product design, manufacturing, procurement and machine maintenance.

Powerful 3D search

- Fast and accurate 3D model search

- Find shapes in complex composite parts

- Optimize management with Metadata

Flexible Implementation

- Easy to use for non-CAD users

- No need for data conversion at the start of an operation

- No need for large-scale system development

Excellent Accessibility

- Compatible with multiple 3D data formats

- Can be linked to PLM/PDM/ERP systems

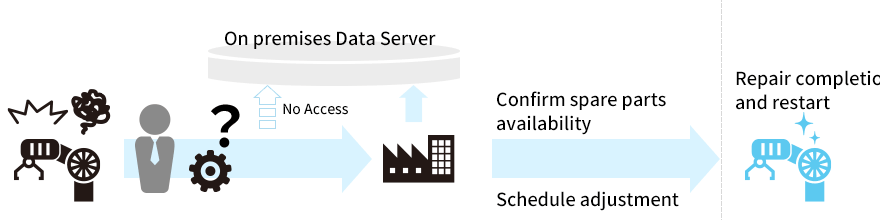

- Accessible from mobile devices

Physna consolidates useful past data lying dormant within

the company and promotes the effective use of 3D data.

Features of

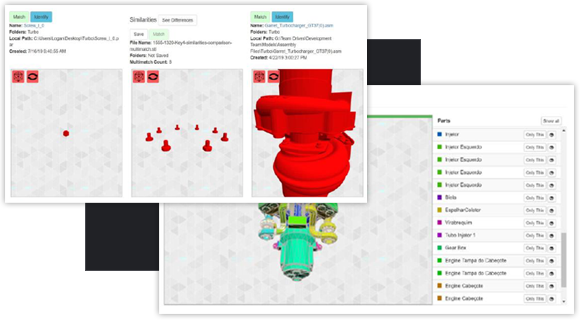

Fast and powerful 3D search and shape comparison

Instantly search and compare similar 3D data from a huge database using the shape of the 3D data as a key.

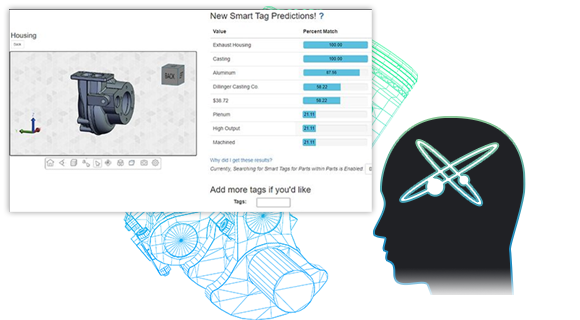

Ever-growing data analysis capabilities

Proprietary AI learns trends to improve data search accuracy

Search for parts in an assembly

Provides layout, substitute parts, and similar data for each component

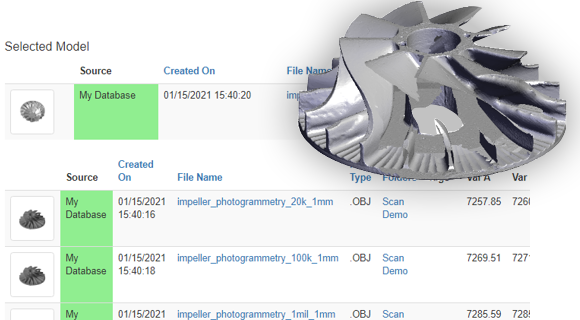

Scan data search

Shape search is possible even for the incomplete

scan data with missing shapes

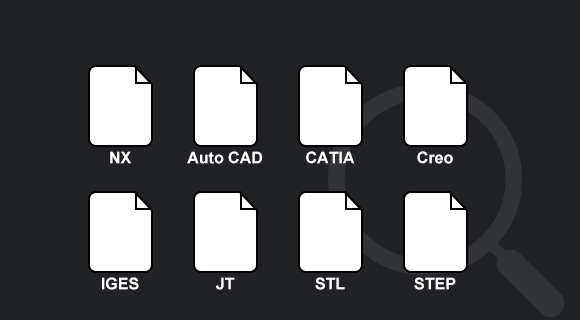

Supports various file formats

All widely used 3D file formats can be

supported for search and analysis

Supports a variety of operational scenarios

Upload data immediately without the need for a server

Advanced security

All data is encrypted and managed

Application examples

Introductory Videos

Physna Technology Overview

Supporting Engineering and Product Design Teams

Why Physna can search for parts

A world enabled by Physna's powerful geometric search

What is Physna‘s PNA (Physical DNA)?

Unique algorithm and advanced 3D deep learning technology

About Physna

Physna is an industry leader in geometric deep learning technology. The company's software bridges the gap between the physical world and digital code by encoding the 3D world through a deeper understanding of the physical properties of real-world objects and their relationships. Physna is building the 3D future of software and is already improving engineering, industrial design and procurement by putting new and powerful search capabilities in the hands of innovators and creators. The company's name is derived from "Physical DNA," that represents the geometric features at the core of the technology.

In July 2021, the company received $56 million in funding with participation from GV (formerly Google Ventures) and Sequoia Capital, with Tiger Global as the lead investor, for a cumulative total of $86 million.

(Note) Major 3D data formats such as CATIA, NX, Creo, Solid Works, AutoCAD, Inventor, STEP, IGES, STL, Parasolid, etc. are supported.

Please contact us for details.

Inquiry

We will provide you with the best solution for your needs. Please feel free to contact us.