SERVICE /

SOLUTION

- Home /

- Service / Solution /

- Testing and Validation Solutions /

- FTI Forming Suite

Optimizing Design for Manufacturing

Forming Technologies (FTI) is part of Hexagon’s Manufacturing Intelligence division. Through tools that optimize the design for manufacturing, material utilisation and cost of sheet metal components, FTI enables better cost engineering, design engineering, and manufacturing engineering.

Solutions

Cost Engineering

Through accurate cost analysis, cost engineering allows designers to define target costs early in the design process. Through simulation technology, it helps improve material utilization, reduce vehicle weight, and tooling development time.

COSTOPTIMIZER® from FTI is a leading cost estimation and material utilization software designed to reduce material costs and limit expensive engineering changes. By combining the capabilities of FASTBLANK, BLANKNEST, PROGNEST & OPTIMIZER, it enables Cost Engineers to develop quotations and estimates for piece part costing. They can do so through the creation of precise blank shape developments, initial formability risk assessment and establishing target costs for sheet metal components.

Design Engineering

Performing quick feasibility studies of sheet metal parts at the design stage can help improve design for manufacturability (DFM) quality. This can eliminate re-work and reduce the number of engineering changes after part design release.

With the FASTFORM® ADVANCED tool, users can quickly and easily evaluate part and process feasibility. They can also determine blank shape and spring back for sheet metal components. CATSTAMP® allows users to evaluate part and process feasibility in addition to determining blank shape and spring back, in a quick and easy manner.

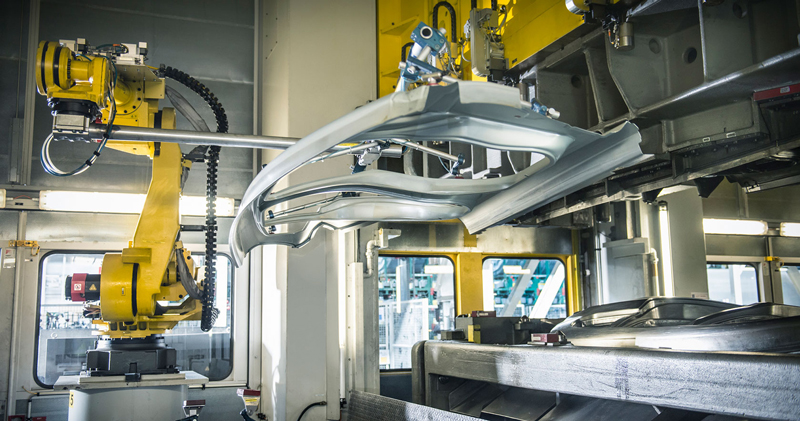

Manufacturing Engineering

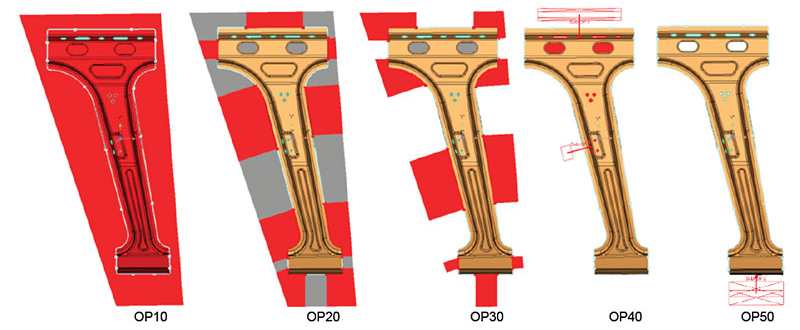

Designers can perform virtual tryouts of stamping and assembly processes to help them identify issues even before building the tooling. This helps to reduce costs and time-to-market, while improving product quality. These solutions can be applied to all types of metal forming, joining, welding and metal-based additive manufacturing.

FORMINGSUITE® PROFESSIONAL allows users in all departments to quickly and easily evaluate part and process feasibility as well as spring back for sheet metal stamped components. The CATIA V5/V6 TRIM LINE DEVELOPMENT solution combines the power of FTI’s Coupled Hybrid Inverse (CHI) solver and CATIA V5/6 for development of complex hems and flanges required for Class A panels at automotive OEM and Tier 1 suppliers. Also, FormingSuite® SCULPTURED DIE FACE helps cost engineers to quickly create and morph die face designs to accurately capture the true metal forming process.

TEL:+91-80-6178-2000 /

E-mail:contact.sid@solize.com