SERVICE /

SOLUTION

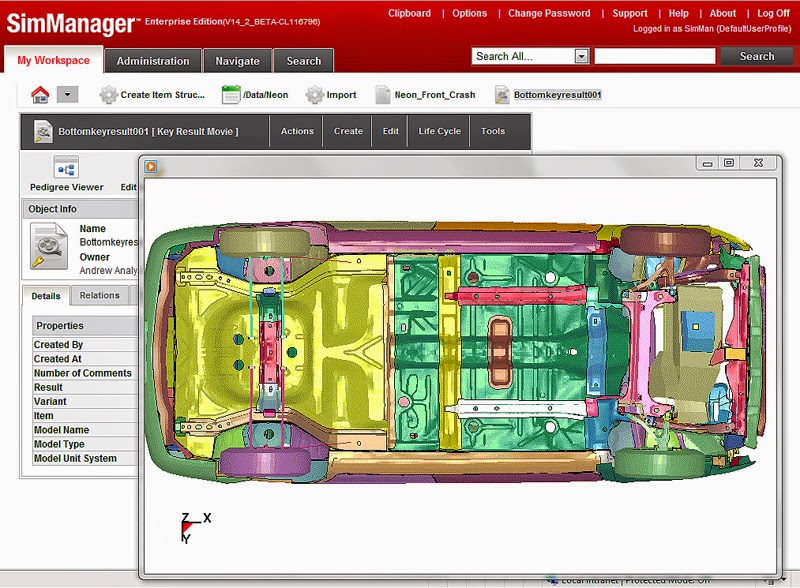

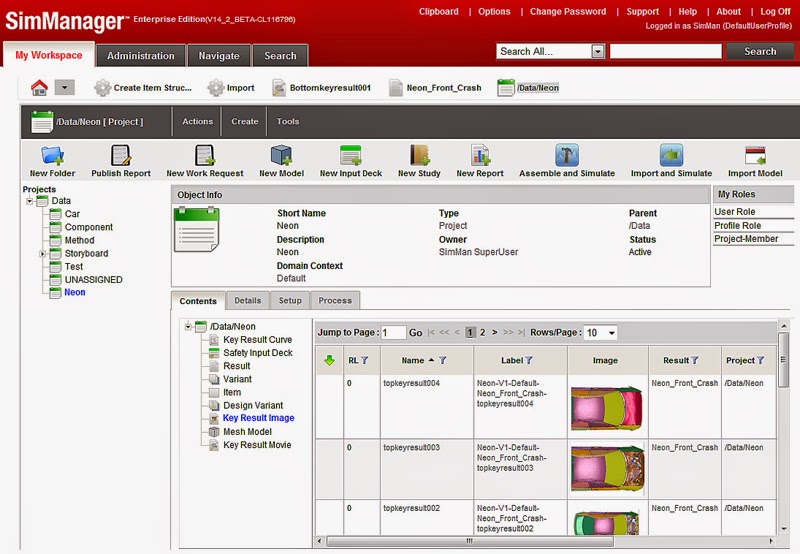

Web-based Simulation and Test Data Management System

MSC Software offers a web-based simulation and test data management system that is equipped to handle of large volumes of data generated by various simulation processes such as FEA, CFD, and Multibody Dynamics.

Given that simulation generates a significant amount of data, it has a big role to play in product design and development, especially with respect to helping companies identify problems early in the design cycle. However, this data needs to be stored optimally to avoid increased cost of data maintenance and recovery.

The solution from MSC Software is easily deployable for the entire project life and allows easy extension into new domains.

Key Features

Capture Simulation Data

MSC Software solution helps retain all the data pertaining to a process, thereby ensuring complete traceability of process-generated objects; unlike most traditional Product Data Management (PDM) tools. As a result, engineers and product managers can achieve great productivity and quick return on investments.

Manage Simulation Data

With SimManager, engineers can efficiently manage large amounts of simulation data obtained from various sources. In addition to capturing data, it allows for seamless management of import and export of several objects in a single environment.

Given the simple and easy flow of data, SimManager offers a flexible working environment. This solution finds applications in the aerospace, automotive, and pharmaceutical industries.

Collaborate Effectively

SimManager doesn’t stop with managing large volumes of data, but also enables engineers to collaborate and co-create. It contains project dashboards that can be used to track the status of assigned tasks, providing project transparency and enhancing engineering productivity.

Automate your Processes

This software solution allows engineering professionals to automate repetitive tasks. For instance, importing a model file or assembling component models into a run-ready input file is easier. Automation of other simulation processes such as post-processing, reporting etc. is also possible using this feature.

Related Products

TEL:+91-80-6178-2000 /

E-mail:contact.sid@solize.com