CASE

STUDY

- Home /

- Case study /

- Escorts Agri Machinery

Escorts Agri Machinery

Simulation Escorts Agri Machinery

Overview

Established in 1944, Escorts Group is one of the largest engineering conglomerates in India and known world-wide for manufacturing core Agricultural equipment. With valued relationships with technology leaders of the world, Escorts Group has achieved a growing network of more than 800 customer touchpoints and customer base of over 14,00,000 happy customers. Pioneering the farm mechanization in India, Escorts Agri Machinery has helped transform the agricultural and farmland challenges of rural India into yields of opportunity. Escorts Agri Machinery has committed itself to enhance India’s agricultural productivity by adding value to the farmer’s life and enriching the value of Rural India’s most precious means of livelihood - agriculture. Escorts Agri Machinery currently manufactures a technologically powerful range of tractors under two-star brands – Farmtrac & Powertrac.

Team

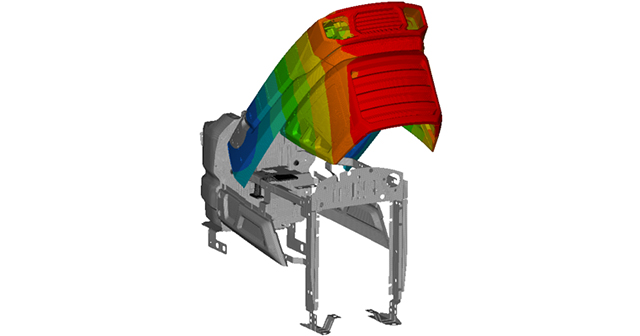

The primary objective of the Escorts CAE team is to check and validate part/assembly design of the tractors and other agricultural/farm equipment. Various FEA analyses, Structural, MBD NVH, FOPS, ROPS and Durability analyses are performed by the team to develop best-in-class products.

Challenges

- To validate the model and reduce the tests and prototypes.

- Replicate realistic FE model with a suitable structural design that ensures the essential strength and stiffness.

- Predict the failure and safety of the machine in the product development stage itself.

Products Used

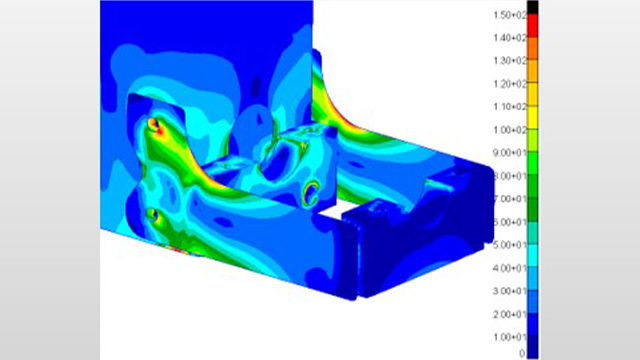

Through MasterKey tokens, MSC ADAMS, MSC Nastran, MSC Marc, MSC Fatigue & MSC Patran were used to help develop realistic models with desired performance efficiency. MSC Patran was used for pre-processing the models and analysing the results, MSC ADAMS helped in virtual testing of the models to predict loads in dynamic conditions, MSC Nastran & Marc were used to calculate the strength, and MSC Fatigue helped in estimating the life of the product.

Approach

The continuous support from the SOLIZE technical team and the powerful Hexagon MSC Software products helped the Escorts CAE team address various challenges in developing realistic and different virtual models, which covered the criteria of broader design requirement as per various system designs.

- The number of prototypes were reduced

- The product development time cycle was minimized

Benefits

Escorts CAE team effectively used Hexagon MSC Software’s simulation solutions which significantly reduced the modeling challenges and enabled the team to develop more robust simulation models which correlated with actual test conditions.

- Due to reduced number of physical tests in the early stages of designs and lesser number of prototypes, significant savings were achieved in cost and time. Durable and optimized components were designed with the help of simulation software during the design cycle of the vehicle.

- There is a significant reduction in the warranty cost due to reduced field failures. The reduction in field failures resulted in improved customer satisfaction and greater customer loyalty.

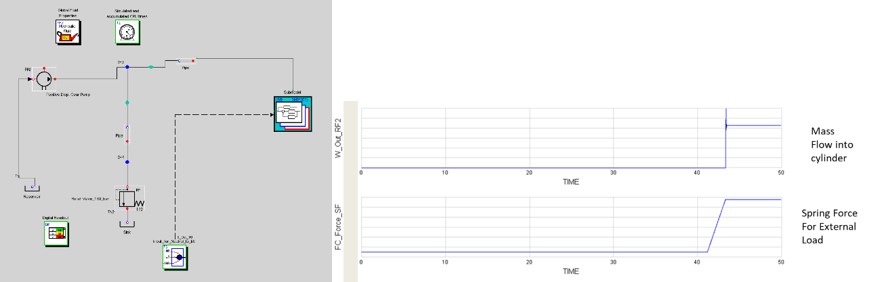

Calculations with 1D Hydraulic Circuit Tractor: Easy 5

Calculations with 1D Hydraulic Circuit Tractor: Easy 5

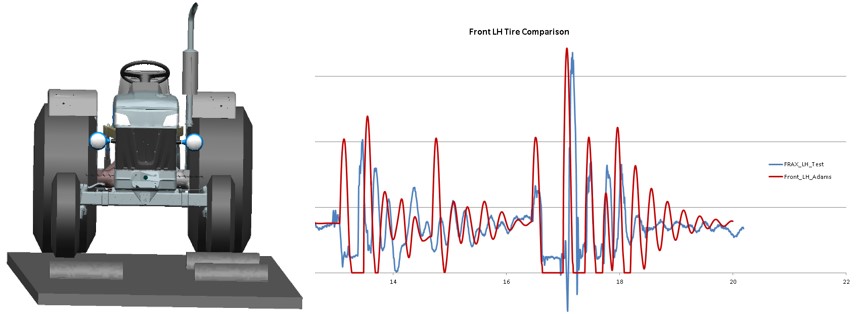

Test-CAE correlation: MSC ADAMS

Test-CAE correlation: MSC ADAMS