SERVICE /

SOLUTION

- Home /

- Service / Solution /

- Testing and Validation Solutions /

- Simufact Products

Best-in-class Manufacturing Process Simulation Solution

Simufact provides modular solutions which can be effectively leveraged for optimizing manufacturing processes by minimising costs and time to market, while ensuring accurate results. The three product lines Simufact Forming, Simufact Welding, and Simufact Additive, cover a broad and ever growing range of forming, joining, and additive manufacturing processes: forging, cold forming and rolling processes (ring-rolling, sheet metal forming, mechanical joining and heat treatment, etc.) along with all common welding processes and newly powder bed fusion AM processes. The modular approach in these product lines is based on the product philosophy that a special manufacturing process needs special functionality. Consequentially, the users can greatly benefit from the process-specific modules, in contrast to general-purpose tools that strive to cover all processes.

Key Solutions

Simufact Additive

Simufact additive is considered as one of the most resilient, scalable process simulation environments for predicting the distortion in metal additive manufacturing. It provides a robust simulation environment for powder bed additive manufacturing processes such as SLS, SLM, LBM, DMLS, and EBM. It is widely used for simulating processes from end to end such as powder bed fusion, heat treatment, pressurization, detaching part, removal of support structure as well as Hot Static Pressing (HIP) process prediction of distortion, residual stress and material densification. This tool can be used to run simulations in Windows and Linux environments. It uses efficient computational methods to predict shrinkage, residual stresses, component warpage, the optimal location of the part, support structure. It also helps predict the influence of several components in the build space and calculate the deformation of the base plate.

Production engineers can leverage this tool to predict potential distortions and residual stresses and this will help them to ensure quality with the “right the first time” approach. They can also optimize their 3D printing process by taking the process control variables into consideration to reduce material wastage, time, and other critical resources. It can also be used to analyze the influence of material selection, powder characteristics, Power vs speed, support/internal structures, Build path / hatching pattern.

Simufact Forming

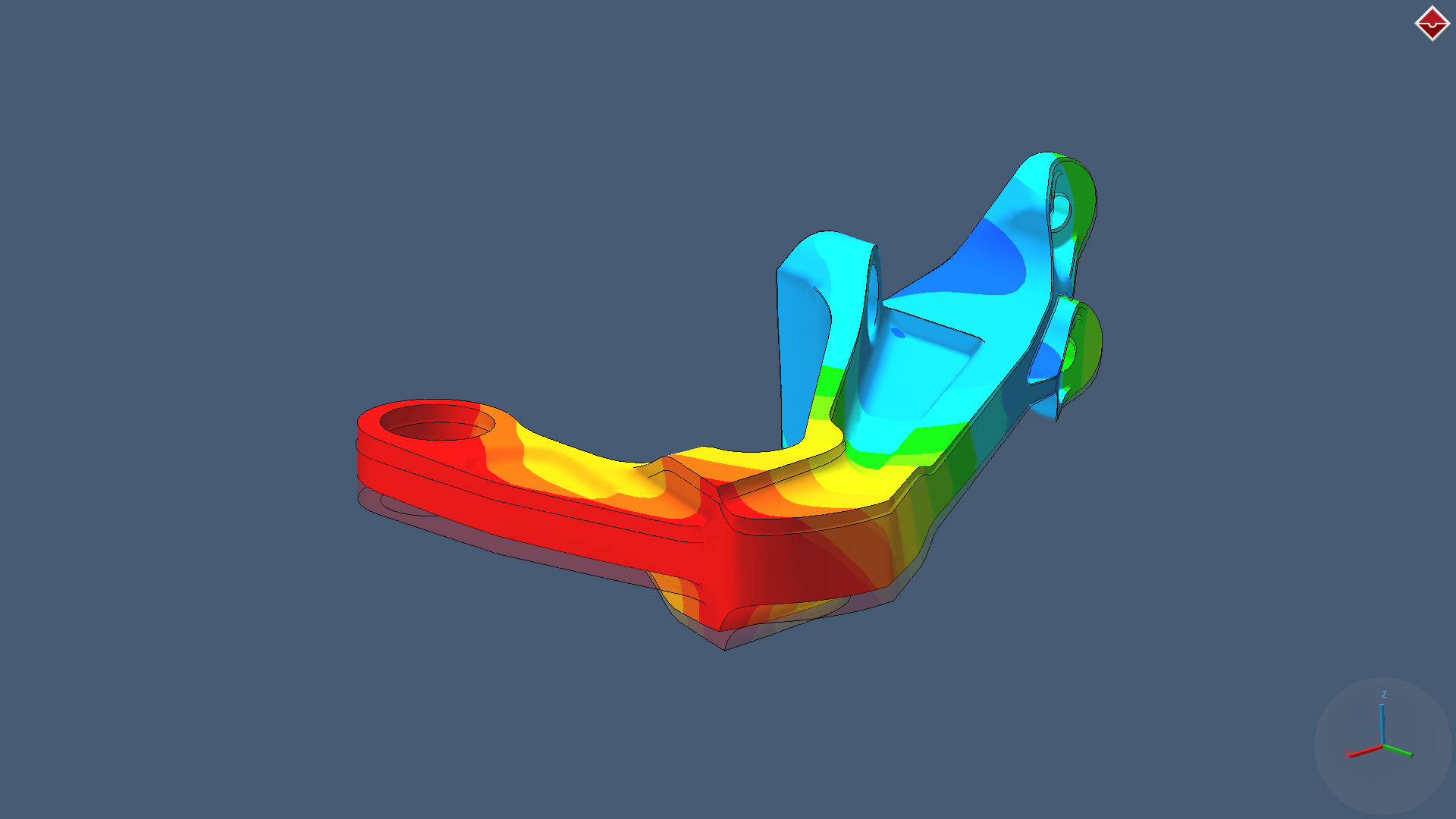

Simufact forming, a comprehensive spectrum of forming technologies assists engineers in obtaining a realistic portrayal of processes by providing complete 3D functionality and 3D representation of all components and tools. Key aspects impacting processes such as the kinematics of the machine, non-linear behavior of the workpiece, friction and contact between the forming parts and tools, and thermodynamics of the process are captured efficiently resulting in accurate simulations with Simufact forming.

Multiple modules being available to address a range of processes, the core module of the forming hub encompasses requisite key functionalities such as GUI, solver, and material database, etc, which are necessary for the operating and handling ability of the simulation software. Simufact forming also offers cold forming and hot forging simulation capabilities. Users have the flexibility to choose from sheet metal forming, rolling, ring rolling, mechanical joining, heat treatment, and open die forging to enhance their simulation capabilities. Optional modules are available to assist with die stress analysis and microstructure calculations, CAD import, customization, faster performance and access to material databases.

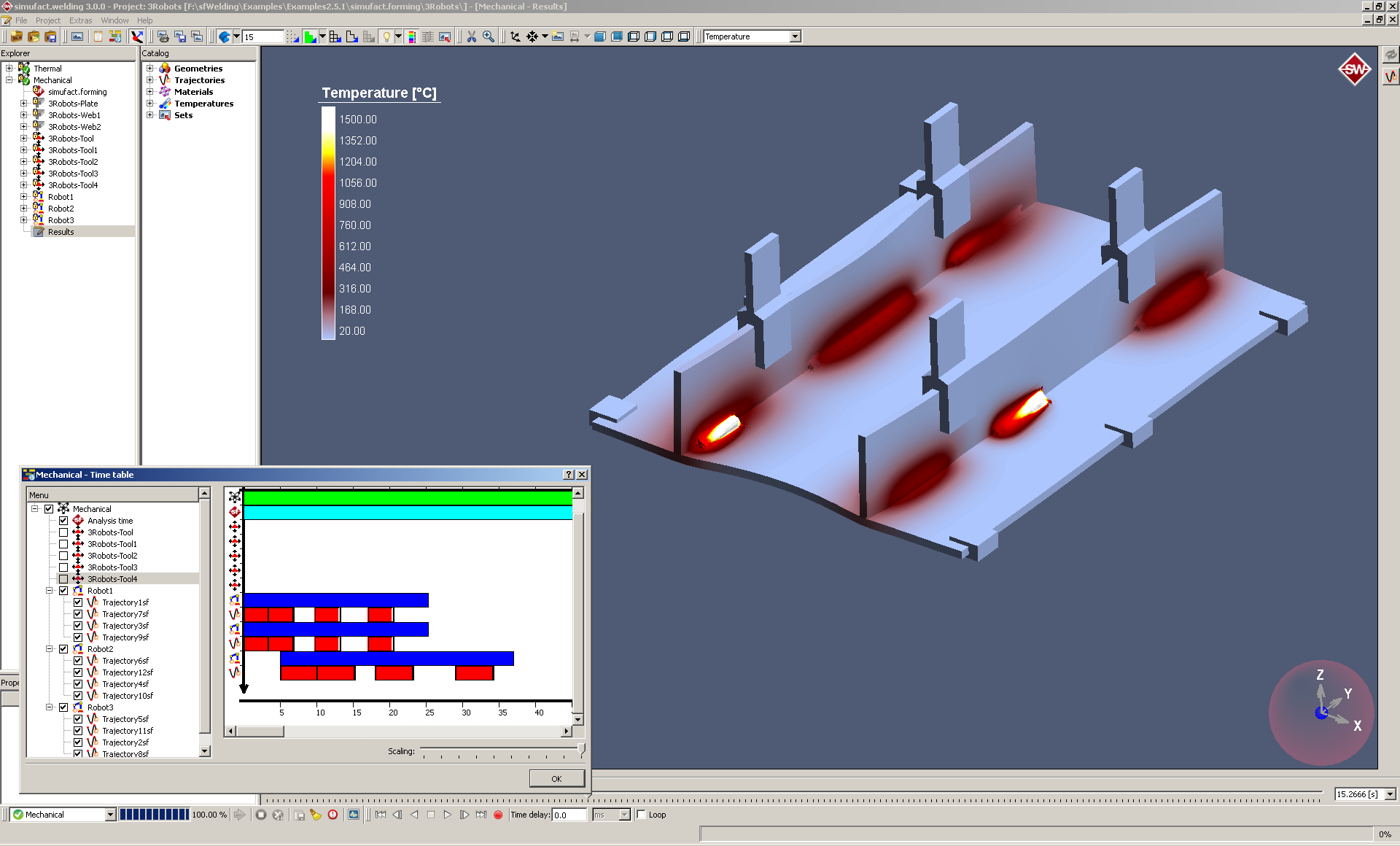

Simufact Welding

Our robust technology solution, Simufact Welding, is invaluable in simulating complex welding processes with multiple welding sequences and predict component distortions while taking into account the phase transformations occurring during the process. It enables the users with actionable insights into the properties of the weld seam and a host of welding defects such as hot cracks. These insights help the users in addressing challenges and optimizing prior to implementing the process. For users wanting to simulate a combination of process chains with upstream and downstream welding processes, Simufact welding can be used along with Simufact forming for better results. The easy data transfer allows consideration of the forming history along with strength analysis of simulated welded seams.

TEL:+91-80-6178-2000 /

E-mail:contact.sid@solize.com