SERVICE /

SOLUTION

- Home /

- Service / Solution /

- Testing and Validation Solutions /

- Acoustics

Robust Acoustic Performance Optimization Solutions

The acoustic signature of any product is highly essential for branding purposes as well as limiting anticipated noise pollution for it to be well-accepted by the customer community. Besides, the industry-specific noise regulations should also be considered by engineers early on in the product development cycle to avoid additional costs of rework and delays in the product launch.

Leading engineers and product designers can leverage MSC’s cutting-edge acoustics solution to understand the roles of noise sources and all possible transmission paths. Equipped with robust technology and highly efficient solvers, MSC’s acoustics solutions help engineers to study the complex interactions between structures and fluids. The solutions built on finite and infinite element-based technology are easy to implement, intuitive and known to work efficiently on large and complex models.

Key Features

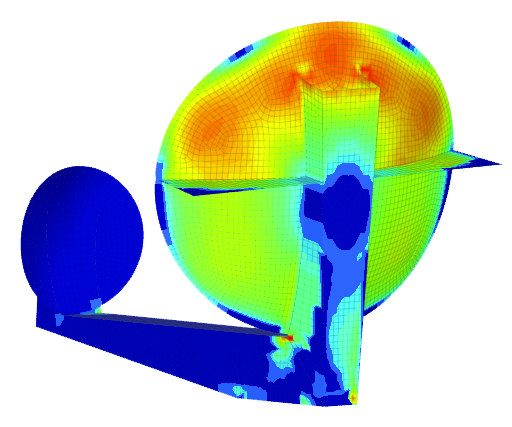

Acoustic Radiation

With our extensive acoustic analysis capabilities, engineers and product designers have the flexibility to extract acoustic modes, analyze sound radiation, model absorbing walls and study sound propagation in ducts, intake and exhaust lines and distribution systems in buildings. Due to the sound radiation analysis in a fluid or enclosed cavity capability, MSC’s acoustics solutions have found immense application scope in the aerospace and automobile industries.

Vibro-acoustics

Modeling the behavior of structural components and fluids is essential to study the interaction of structural vibration with the adjacent fluid. MSC’s acoustics solutions enable users to seamlessly analyze a host of interior and exterior acoustic challenges. Designers can incorporate complex, realistic boundary conditions along with appropriate structural material properties of trim components for damping behavior.

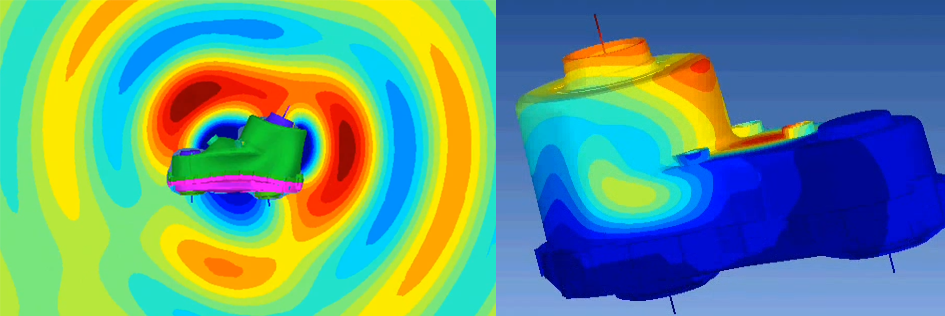

Aero-acoustics

Aero-acoustics essentially is concerned with noise generated due to noise sources like turbulent flow within a fluid and its propagation within the fluid. Engineers can recover the aerodynamic noise sources from flow simulations performed with commonly used CFD codes that further can be used to compute the aero-acoustic noise in a highly efficient manner. Aero-acoustics capabilities can also be combined with vibro-acoustics that enable the users to model complex aero-vibro-acoustic problems.

Key Applications

Wide-scale Industry Implementation

MSC’s acoustics solutions enabled with robust, cutting-edge technologies have found applications in a wide range of industries such as aerospace, automotive, electronics, machinery as well as consumer goods. Aircraft designers can leverage these solutions to analyze sound transmission through cockpit and fuselage. The solutions can be leveraged in consumer goods such as telephones, headsets, loudspeakers, musical instruments, hearing aids, etc.

Acoustic Modeling

MSC’s reliable acoustics solutions can be leveraged for modeling standard and convected acoustics, modeling transmission through flexible walls, modeling active structures with piezoelectric materials, Dissipation mechanisms such as visco-thermal losses and acoustic absorption, Simulation of complex multilayered structures with composites material models, modeling of liners accurately including the flow effects, 2D, Axisymmetric and 3D analysis, acoustic absorption prediction, Transient CFD followed by acoustic radiation, visco-thermal elements for modeling thin air layers or thin tubes, Heterogeneities such as complex flows and temperature gradients and basic harmonic analysis.

Related Products

TEL:+91-80-6178-2000 /

E-mail:contact.sid@solize.com