COLUMN

Used Powder Recycle of 3D Metal Printing

2018.02.01

3D Printing Direct Metal Printing

During Metal 3D printing process, some particles are melted to make a product.

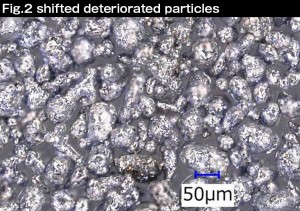

And the other particles are not melted and reusable. This used but unmelted powder contains particles, which were deteriorated during manufacturing process, through melting and solidification by laser and heating and scattering. By removing these particles, you can stabilize the quality of the products.

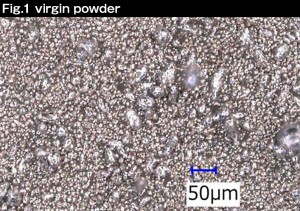

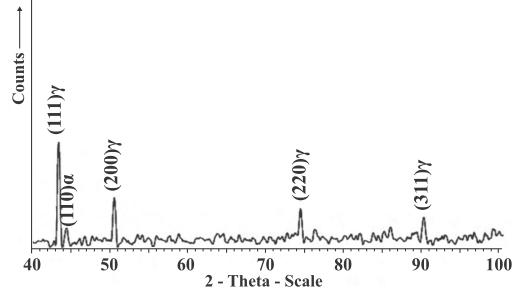

When talking about deterioration of material, it is mainly about change in size and shape of the particle and surface condition. Particle shape of virgin material has relatively high sphericity but as it is reused multiple times, several particle stick together and loss sphericity and gain size. These deteriorated particles reduce fluidity and cause miss feed of material and coarsened particle make unexpected contact with the product and cause deformation. Also, when particle surface is oxidized, metal powder becomes like it is covered by the shell of higher melting point material and fails to melt the powder fully. As you can see, deteriorated particles lead to poor quality products.

To prevent these problems, it is important to remove deteriorated particles using sieve, when recycling the material. In recycling process, mesh size is very important because if the mesh size is too big, it cannot eliminate coarsened particles, and if it is too small, it might eliminate too much material and decrease yield rate, and take too much time recycling.