COLUMN

Defects Found in Horizontal Cross Section of 3D Metal Printing

2018.04.02

3D Printing Direct Metal Printing

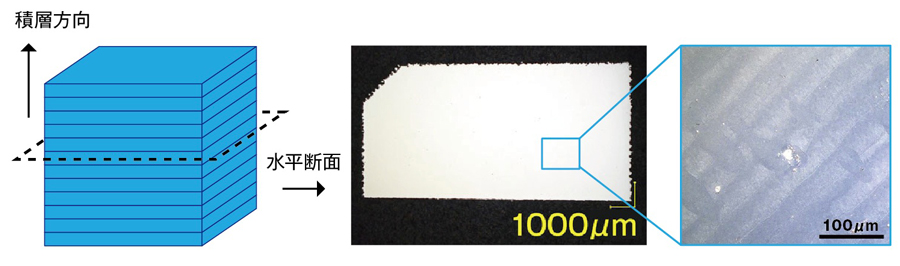

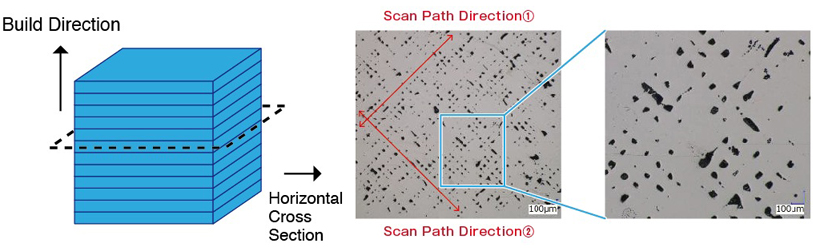

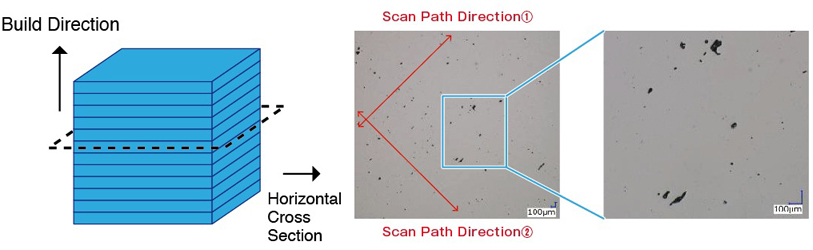

As mentioned in Vol.5, we, SOLIZE, set scan direction so that the next layer scans perpendicularly. When these scan path interval are too wide, detect appears along the scan path.

↑ Fig.1 Before scanning parameter is Adjested

↑ Fig.1 Before scanning parameter is Adjested

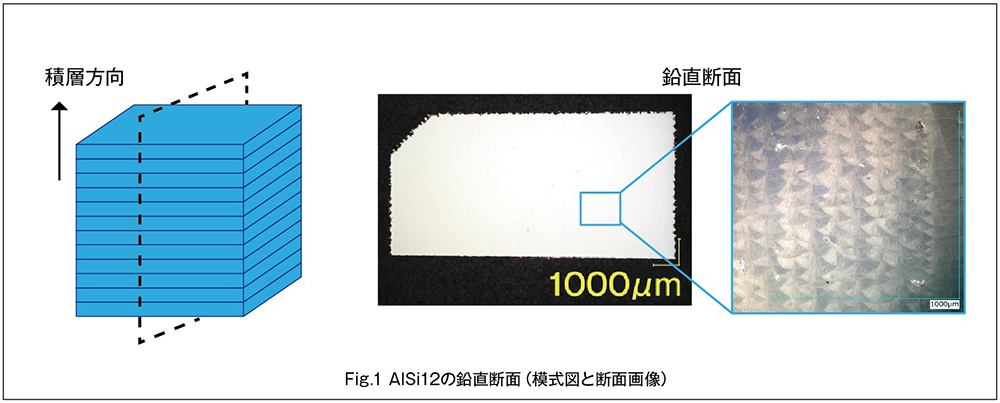

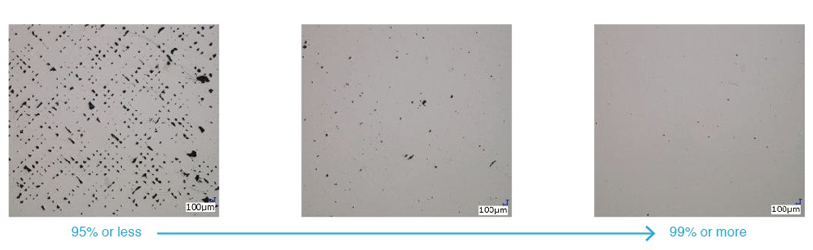

As we can see in Fig.2, narrowing the interval of the scan path increases the density of the 3D print product.

↑ Fig.2 After scanning parameter is Adjusted

↑ Fig.2 After scanning parameter is Adjusted

↑ Fig.3 Adjusting the Parameter for Higher Dense

↑ Fig.3 Adjusting the Parameter for Higher Dense

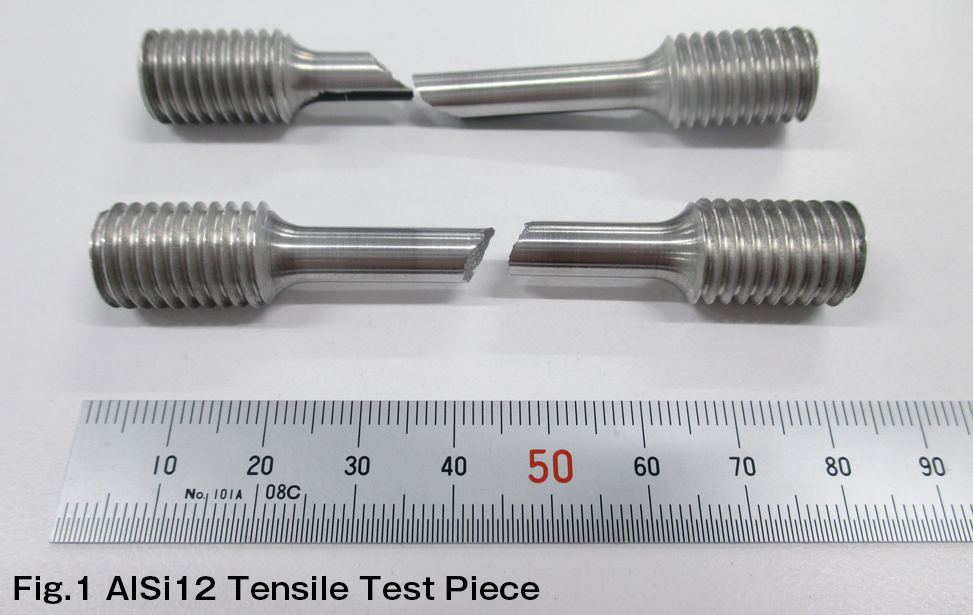

SOLIZE also conducts parameters adjustment on the material provided by the customer and research whether the material can be used for 3D metal printing or not.